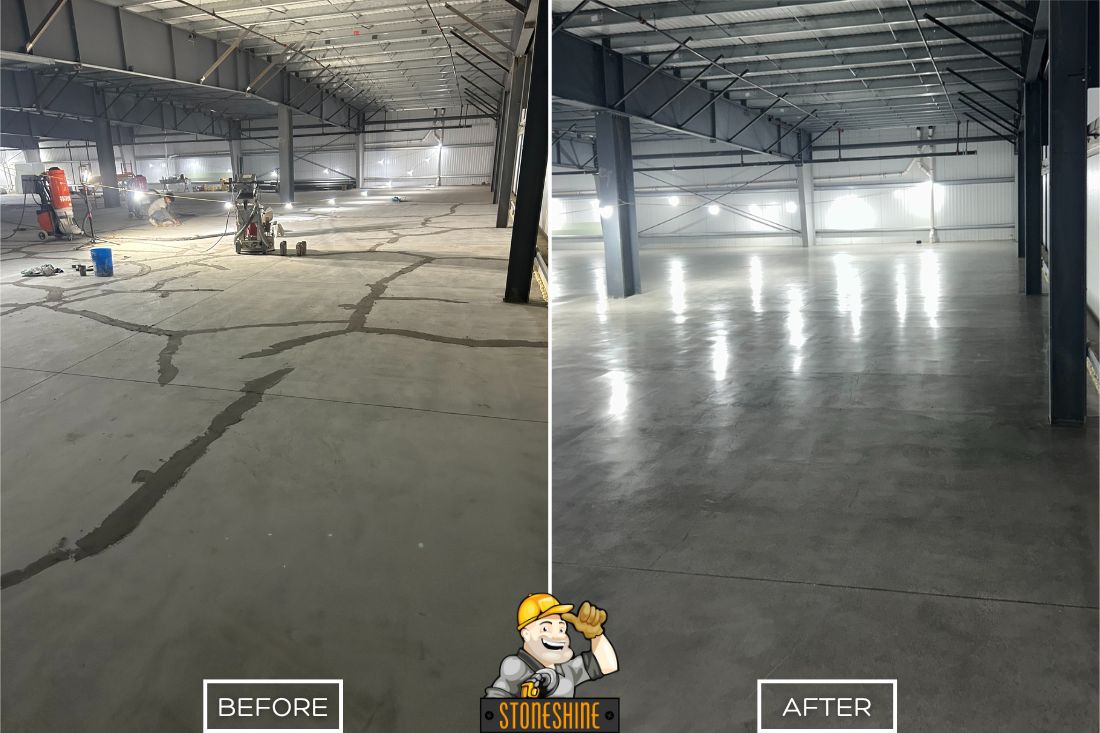

Surface Assessment and Preparation

We began by inspecting the concrete floor to evaluate damage, uneven areas, and cracks. A comprehensive cleaning was conducted to remove debris and stains, ensuring optimal adhesion during the polishing process.

Crack Repair

Before grinding, cracks were filled with industrial-grade epoxy to ensure structural integrity and create a uniform base. This step is essential for smooth and long-lasting results.

Concrete Grinding

Using heavy-duty grinders, we performed multiple passes to remove imperfections, old coatings, and stains. The grinding process progressively refined the floor to achieve a smooth and level surface.

Polishing the Concrete

The floor was polished in several stages using diamond abrasives. We gradually increased the grit levels to create the desired sheen, balancing aesthetics and functionality for an industrial setting.

Application of a Protective Sealer

To ensure durability, we applied a high-performance penetrating sealer. This protective layer resists stains, minimizes wear, and enhances the polished finish, making it ideal for industrial use.